- Description

- Reviews (0)

Description

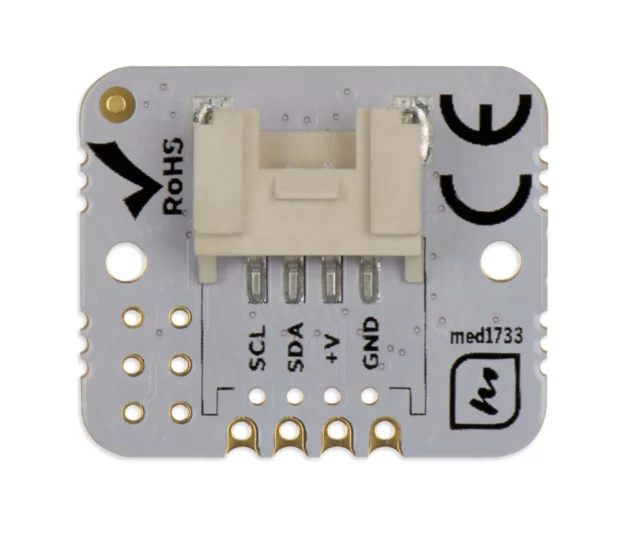

tinyLiDAR is the highest performing VL53L0X based ToF ranging module currently available and also the easiest to use – why not use it on your next project? Read more about tinyLiDAR here.

Features

- Small Size

- Light Weight

- Long Range

- Pre-calibrated by us before shipping

- Firmware version: 1.4.1

- Industry standard “Grove” connector on reverse side of PCB is to be used with suitable 4 pin Grove cables.

- Note: One “Grove to Male Header Pins” cable is included with each tinyLiDAR, you may purchase more if desired here.

NOTE: Quantities are currently limited due to a GLOBAL chip shortage. Please contact us if you need large volumes.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.